Table-top VMM Micro-Vu Vertex 261

The Micro-Vu Vertex 261 is a table top system equipped with a high-resolution camera-based measuring system to get fast, accurate measurements on a wide variety of parts. Vertex can be configured with additional measurement probes and sensors.

Vertex provides vivid pictures through a programmable optical and digital zoom, supports sensitive touch probe accessories allowing measurement of smaller intricate geometry, and high speed vertical distance measurement sensors for scanning capability that covers both specular and diffuse parts.

Vertex includes our InSpec Metrology Software®, which provides point-and-click simplicity, proprietary edge detection, advanced lighting control and calibration, multisensor integration, automated calibrations, and a clear display of measurement data and tolerances.

Micro-Vu Vertex 261 Features

- High resolution digital camera.

- Programmable optical and digital zoom.

- Integrated electronics design, for better system performance and serviceability.

- Advanced proprietary motion control ensures high accuracy measurements at high speed.

- Supports sensitive touch probes accessories.

- Programmable profile, surface and coaxial lights.

- Single USB connection to computer.

- Integrates high speed vertical distance measurement sensors for scanning capability.

- Supports RSD-60 Rotary Device.

- Includes automated calibration procedures.

Micro-Vu Vertex 261 Accessories

|

TOUCH PROBE

|

Integrate vision and touch probe measurements with the Vertex and Excel machine models. Touch probe measurements

include an automatic approach vectoring and solution iteration. The touch probe kit includes a multi-port probe rack designed

to kinematically mount to the machine. InSpec software provides an intuitive probe assembly interface, automated

probe calibrations, and probe docking.

|

|

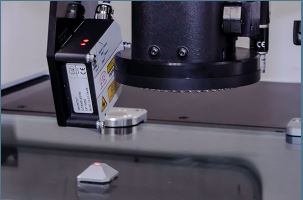

Micro-Vu Multisensor Measuring Systems are equipped and ready to incorporate laser triangulation sensors.

Specular and diffuse mode configurations are available. The distance sensor collects data as it moves between

two programmed XYZ locations, ideal for surface flatness and Z distance measurements.

|

DISTANCE SENSOR

|

|

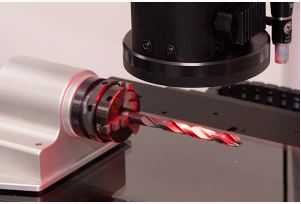

RSD-60 ROTARY

|

The RSD-60 Rotary device can be mounted vertically or horizontally on the Vertex and Excel machine models.

InSpec software integrates the rotary seamlessly and offers an intuitive on-screen interface. The rotary allows rotating

parts to a position relative to a coordinate system or the current position. This device is commonly used for measurement

of medical and dental parts, bits, cutters, valves, fittings, and multi-sided parts

|

SPECIFICATIONS

| PHYSICAL |

VERTEX 261 |

| Measurement Volume [mm] |

250 × 160 × 160 |

| Stage Capacity [kg] |

10 |

| Exterior Dimensions [mm] |

755 × 1130 × 1075 |

| Machine Weight [kg] |

100 |

| XY Max Speed [mm/s] |

250 |

| Z Max Speed [mm/s] |

100 |

| Linear Resolution [µm] |

0.1 |

| ELECTRICAL |

VERTEX 261 |

| Input Voltage [VAC] |

100-240 |

| Power Consumption (Max) [W] |

120 |

| Power Consumption (Idle) [W] |

45 |

| Power Consumption (Sleep) [W] |

35 |

| ENVIRONMENTAL |

VERTEX 261 |

| Operating Temperature [°C] |

18-27; <1 change per hour, <2 change per day |

| Storage Temperature [°C] |

0 – 50 |

| Relative Humidity |

30%-80% (Non-Condensing) |

| Sound Level [dB(A)] |

< 70 |

| Max Altitude [m] |

4000 |

More Measuring Instruments at: Mitutoyo, Unimetro, ….

Micro-Vu is an automation company specializing in 3D measuring and robotics. Technologies include robotics, image processing, motion control, precision mechanics, 3D software development, lasers, sensors, CNC machining and machine learning.

Micro-Vu designs and manufactures in a highly-automated factory at its campus in Windsor, California near the Russian River. Micro-Vu was established in 1959 and is privately-held. Micro-Vu is a non-smoking campus.

Micro-Vu’s customers are manufacturing companies making a variety of products such as smartphones, medical devices, automobiles, OLED TVs, electronic components and aerospace products. Micro-Vu machines are used in manufacturing facilities around the world.

Micro-Vu offers paid internships for local students, paid internships for non-local students that may include housing, and regular full time positions in production, manufacturing, engineering and business economics. Those who work at Micro-Vu must be highly-motivated, capable and passionate about bringing the best possible products and technologies to the market.