Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on back-order

|

Models |

MC-1000 |

|

Weighing capacity |

1100 g |

|

Minimum weighing value |

0.0001 g |

|

Repeatability (standard deviation) * 1 |

0.0005 g (for 1 kg) |

|

Linearity |

±0.003 g |

|

Sensitivity drift (10 to 30°C / 50 to 86°F) |

±2 ppm / °C |

|

Accuracy immediately after internal calibration * 2 |

±0.010 g |

|

Operating environment |

5°C to 40°C (41°F to 104°F), 85%RH or less (no condensation) |

|

Display refresh rate |

5 times/second or 10 times/second |

|

Display mode * 3 |

Gram, kilogram (for MC-100KS only), ounce, pound, pound-ounce, troy ounce, metric carat, momme, pennyweight, grain, counting mode, percent mode, density mode, and a user-programmable unit |

|

Standard interface |

RS-232C |

|

Weighing pan size |

128 x 128 mm |

|

External dimensions |

210 (W) x 317 (D) x 86 (H) mm |

|

Net weight |

Approx. 4.6 kg |

|

Power consumption |

Approx. 11 VA (supplied to the AC adapter) |

* 1 Repeatability when the auto-centering pan or an automatic weight loader is used under good environmental conditions.

* 2 Accuracy immediately after internal calibration performed under good environmental conditions. The values are for the weighing capacities.

* 3 Either tael (Singapore/HK jewelry/Taiwan) or tola can be added upon request.

It’s not easy to find high performance, quality mass comparators that meet your budget, is it? Discover how A&D, an ISO17025 accredited calibration laboratory as well as being a weighing equipment manufacturer, can finally solve such problems for you —.

High resolution balances like the MC series can respond to even the slightest environmental disturbances. For smooth and accurate mass comparison, the MC series is equipped with a special

stabilizing function that copes with the effect of drafts or vibrations.

Using the internal mass, you can ensure the balance accuracy with one key press when changes to the environment (such as temperature or location) take place. The internal mass value can be

corrected as necessary.

Even under a perfectly controlled weighing environment, there still remain errors that can arise from operation. The following tools are effective in managing such errors:

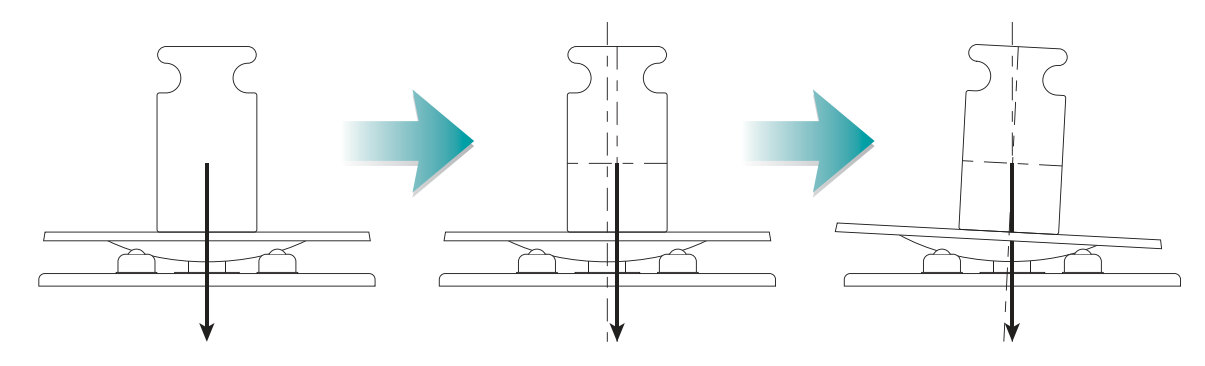

Corrects eccentric loading automatically by bringing the mass to the center.

– Resist inks on flat panels (glass)

– Coating materials on silicon wafers

– Moisture contents of catalysts

– Solder pastes and sealing materials on electronic parts

– Resins used for LED lenses

– Surface materials on optical lenses

– Grease in miniature bearings for hard disks

– Medicines in pharmaceutical manufacturing – from full flow to minute flow

– Discharges (losses in weight) from feeders

– Wear volumes of metallic materials

– Cutting dust (contaminants) left on mechanical parts

– Particles caught by filters

– Fill ration of hydrogen gas

– Gasified components

– As precision check-weighing sensors with wider ranges