Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

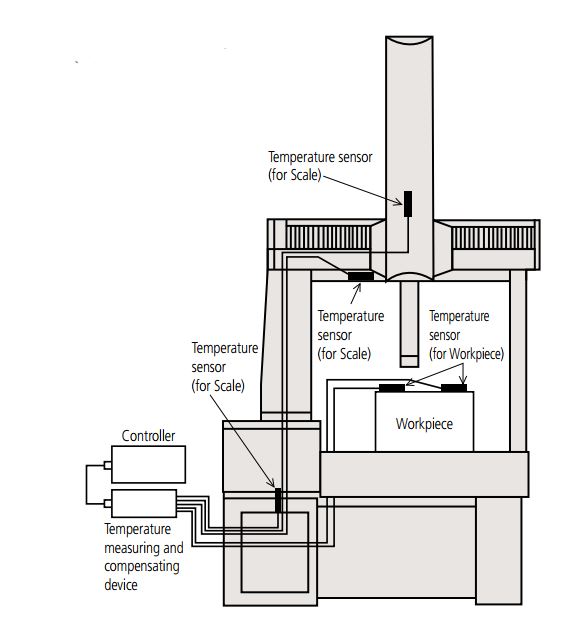

In the past, the accuracy of CMMs could not be guaranteed unless they were installed in constant temperature rooms.The temperature compensation feature guarantees accuracy under temperature conditions of 16-26 °C. This feature measures the temperature of the workpiece and that of the measuring machine, calculates what the measurement value would be at 20 °C, and outputs this value as the measurement result.

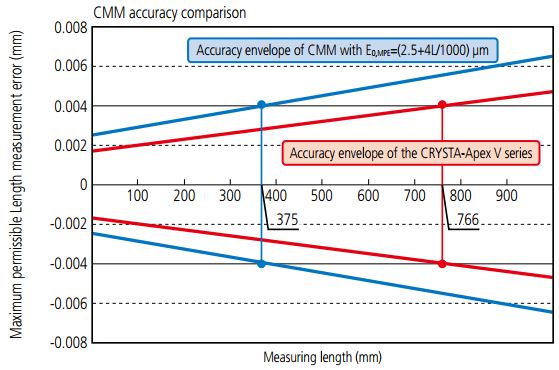

The CRYSTA-Apex V Series guarantees a maximum permissible length measurement error or E0, MPE, of 1.7+ 3L/1000 μm. Let’s consider a CMM offering E0, MPE of approximately 2.5+4L/1000 μm, which would generally be considered high-accuracy. If, for example, the required tolerance on a dimension is ±0.02 mm, the uncertainty of this machine would exceed one-fifth of this value* ( ±0.004 mm, as shown on diagram at right) for any measured length over 375 mm. In contrast, with the V Series, the measurement uncertainty remains within one-fifth of the required tolerance for measuring lengths up to 766 mm. Although the difference in the first term accuracy specification between the two machines may seem small (a mere 0.8 μm), the V Series actually offers guaranteed accuracy for more than double the measuring range.

To eliminate causes of dynamic error and deliver high repeatability, data from measurements using scanning probes are processed for stabilization. The probe is kept still for a few seconds when its tip first contacts the workpiece, thereby ensuring that causes of dynamic errors are eliminated as much as possible and making it possible to deliver highly accurate measurement results.

The CRYSTA-Apex V Series offers a maximum drive speed of 519 mm/s and a maximum acceleration of 2,309 mm/s2. Compared with conventional CNC CMMs (with a maximum speed of 430 mm/s and a maximum acceleration of 1,667 mm/s2 ), this amounts to about 100 mm more drive distance one second after starting movement.

The V Series is equipped with a measurement feature that allows users to specify scanning measurement paths (design values). This feature allows for high-speed, high-accuracy scanning by correcting dynamic errors that would otherwise be produced by acceleration and deceleration stresses. Measurement paths can be freely specified for three-dimensional forms as well, which enables intricate workpieces to be measured by tracking precisely along their curved surfaces and contours.

The SP25M is a compact, high-accuracy scanning probe with a 25-mm outside diameter. It is a multi-function CNC CMM probe that can collect data from not only scanning measurements (where the probe moves while in contact with the workpiece to collect massive amounts of coordinate values) but from high-accuracy point measurements as well.

SurfaceMeasure is a laser probe that collects coordinate values of the surface of the workpiece by moving and irradiating laser light over the workpiece. It can quickly obtain massive amounts of 3D surface data.

| CRYSTA-Apex V163012 | ||

| Measuring range (mm) | X | 1600 |

| Y | 3000 | |

| Z | 1200 | |

| Guide method | Air bearings on each axis | |

| Movement speed (mm/s) |

CNC MODE (Key selector switch: AUTO) |

Drive speed each axis: 8 – 400 (max. combined speed: 693) |

| Measuring speed: 1 – 3 | ||

| CNC MODE (Key selector switch: MANUAL) |

Drive speed each axis: 8 – 136 (max. combined speed: 236) | |

| Measuring speed: 1 – 3 | ||

| J/S MODE | Drive speed: 0 – 80 | |

| Measuring speed: 0 – 3 | ||

| Fine speed: 0.05 | ||

| Drive acceleration (mm/s2) | Each axis: 800 (max. combined acceleration: 1390) | |

| Length measuring method | Linear encoder | |

| Resolution (mm) | 0,0001 | |

| Measuring table | Material | Granite |

| Size <stage> (mm) | 1800×4205 | |

| Measured object fixing method | M8×1.25 | |

| Workpiece | Maximum height (mm) | 1400 |

| Maximum mass (kg) | 3500 | |

| Main unit dimensions (mm) |

Height | 4140 |

| Width | 2700 | |

| Depth | 4650 | |

| Mass (kg) <including the installation platform and control device but excluding workpiece> |

Installation platform specifications | 10600 |

| Vibration-damping platform specifications |

11450 | |

| Power requirements | Voltage, Frequency | 100 V – 120 V/200 V – 240 VAC ± 10%, 50/60 Hz |

| Power consumption (including probe options I/F) |

1.5 kW | |

| Air supply | Pressure | 0.4 MPa (4 kgf/cm2) |

| Consumption | 150 L/min under normal conditions (air source: 200 L/min) | |

| Operating temperature range | 10 to 30 °C | |