Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on back-order

High speed and accuracy in measurement is ensured by a redesign of the machine body that has improved rigidity of the structure, and by a remodeled guide mechanism

Uses a digital servo system that processes all control loops for position, speed, and current as digital signals.

The digital servo system offers the following benefits:

(1) Little drift or deterioration with time

(2) Wide dynamic range

(3) Easy implementation of various types of control algorithm

High-performance scanning measurement has been achieved through the improved structural rigidity and incorporation of a newly developed compensation technology

Maximum permissible scanning probing error: MPETHP = 1.3 μm (STRATO-Apex 574)

Maximum permissible scanning test time MPTtHP = 40 sec (STRATO-Apex 574)

(cf. Existing FALCIO Series: MPETHP = 2.2 μm)

MPTtHP = 110 sec.)

*Probe used: SP25M

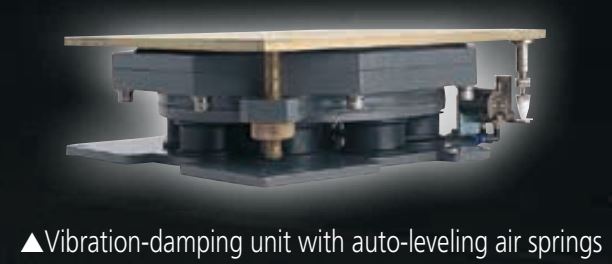

Vibration of the floor where the unit is installed shows up as measurement value variations. The STRATO-Apex Series comes equipped with a vibration- damping unit that uses auto-leveling air springs. The vibration-damping unit not only prevents floor vibrations from reaching the main unit, but also has a function that uses a sensor to detect load changes caused by movements of the individual axes and placement of a workpiece and quickly restores the main unit to horizontal orientation.

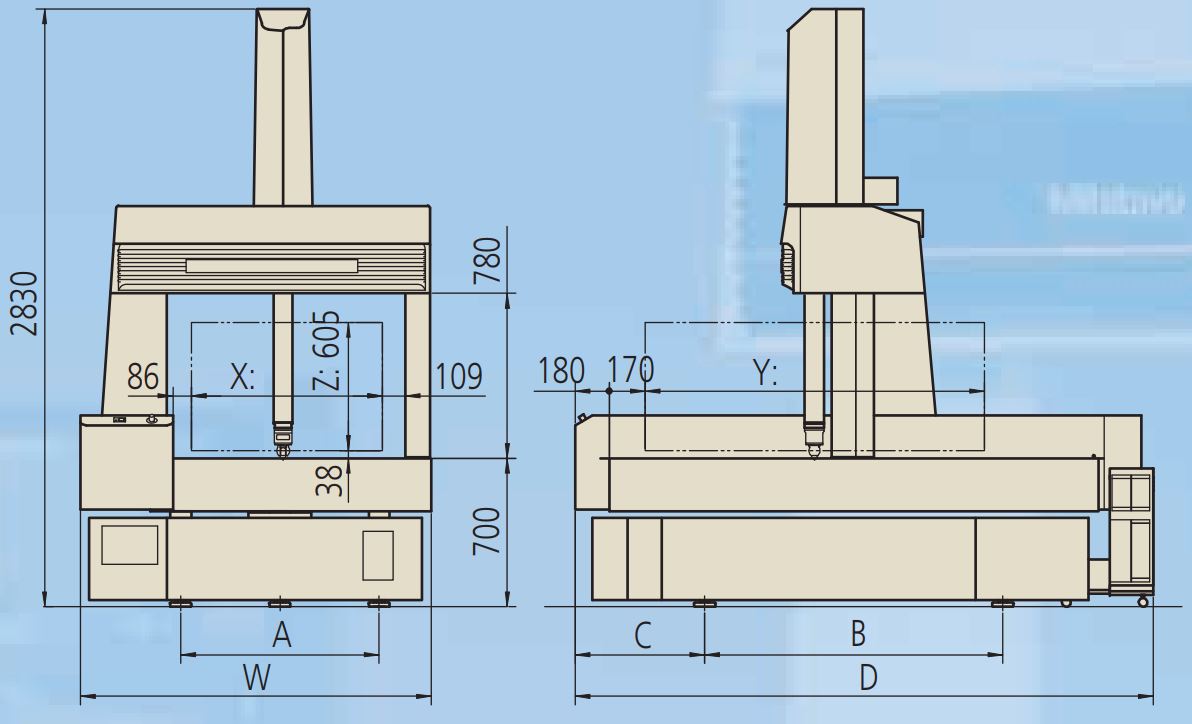

| Model | STRATO-Apex 776 |

| Order No. | 355-502 |

| Type | Moving Bridge Type High Accuracy |

| X-axis | 27.6″ (70mm) |

| Y-axis | 27.6″ (700mm) |

| Z-axis | 23.6″ (600mm) |

| Resolution | 0.0000008″ (0.00002mm) |

| Material | Granite |

| Work Table Size | 33.93″ x 55.90″ (862mm x 1420mm) |

| Tapped Insert | M8x1.25mm |

| Max. Workpiece Height | 30.31″ (770mm) |

| Max. Workpiece Weight | 1102lbs (500kg) |

| Mass (including stand and controller) | 4177lbs (1895kg) |

| Machine Dimensions WxDxH | 57.48 x 73.22 x 111.41″ (1460 x 1860 x 1460mm) |

| ISO | ISO-10360-2:2009 E0,MPE TP200: (1.4+2.5L/1000)μm** SP25: (0.9+2.5L/1000)μm** ISO-10360-2:2009 E150,MPE ISO-10360-2:2009 R0,MPL ISO-10360-4: 2000 MPETHP/MPTTHP ISO-10360-5: 2010 PFTU,MPE |

| Item | STRATO-Apex 776 |

| A | 740 mm |

| B | 700 mm |

| C | 540 mm |

| D | 1860 mm |

| W | 1460 mm |