Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

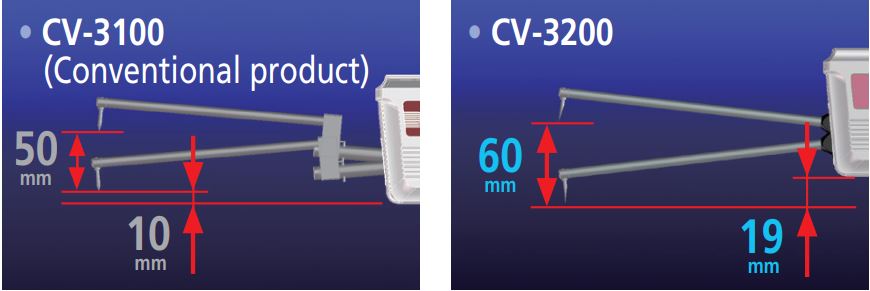

Expands measurement range while reducing workpiece interference Mitutoyo’s newly designed detector arm lowers workpiece interference while expanding the measurement range in the Z1 axis (detector).

The detector includes a safety mechanism (auto stop upon collision) to assure measurement safety even during high-speed movement. If the arm is removed or shifts during measurement, the safety mechanism is triggered and stops the machine.

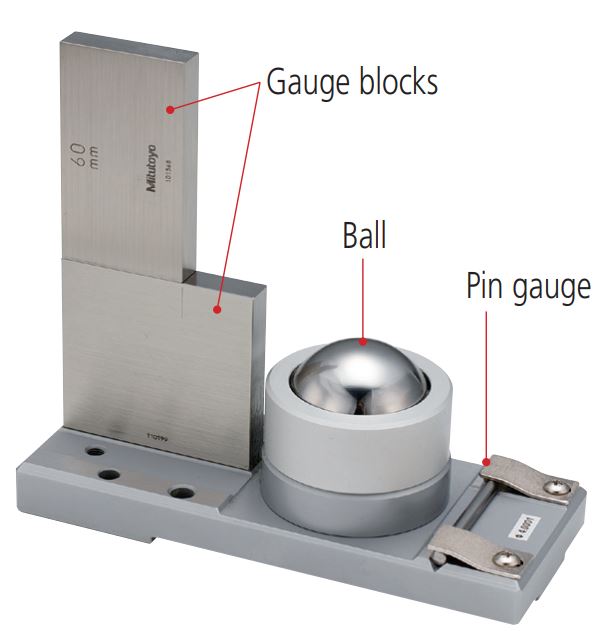

The CV-3200 Series provides a dedicated calibration gage that lets you carry out precise work such as calibrating the Z1-axis gain, symmetry, and stylus radius in a single operation. Calibration of upward measurement is also possible by using Mitutoyo’s optional calibration stage.

Calibration kit for CV-3200 series

The CV-3200 Series features a built-in precision arc scale on the Z1 axis (detector) that allows the arc trajectory of the stylus tip to be read directly, minimizing the detector mechanism error and enabling precision, high-resolution measurement. On the X axis (driver) is a linear scale, allowing high-accuracy full-stroke measurement.

Accuracy ————————————————————————

Z1 axis (detector unit): ± (1.4 + | 2H | /100) μm

H = Measurement height from the horizontal position (mm)

X axis (drive unit): ±(0.8+0.01L) µm*1

L = drive length (mm)

Resolution ————————————————————————

Z1 axis (detector unit): 0.04µm

X axis (drive unit): 0.05µm

*1 These specifications apply to the CV-3200S4/H4/W4. For specifications of other products in the series, see Specifications on page 14.

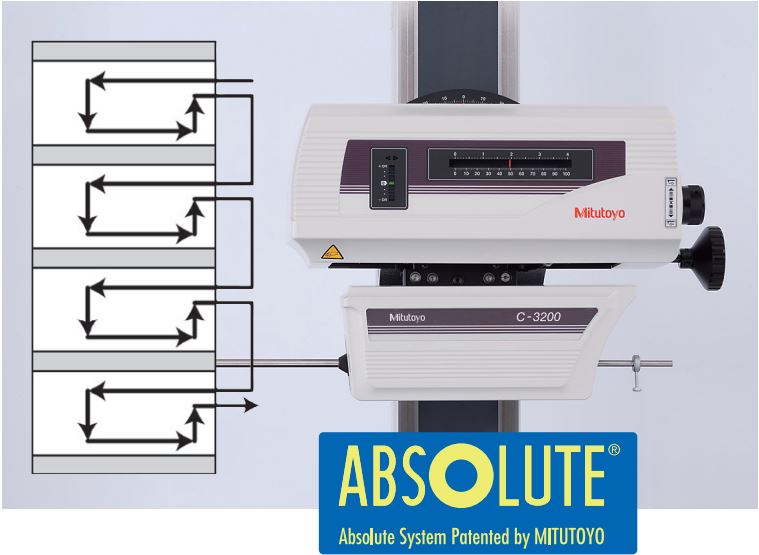

Incorporation of an ABS scale in the Z2 axis eliminates the need for wearisome origin point re-setting conventionally required for every step of repeated measurements over stepped or multiple sections.

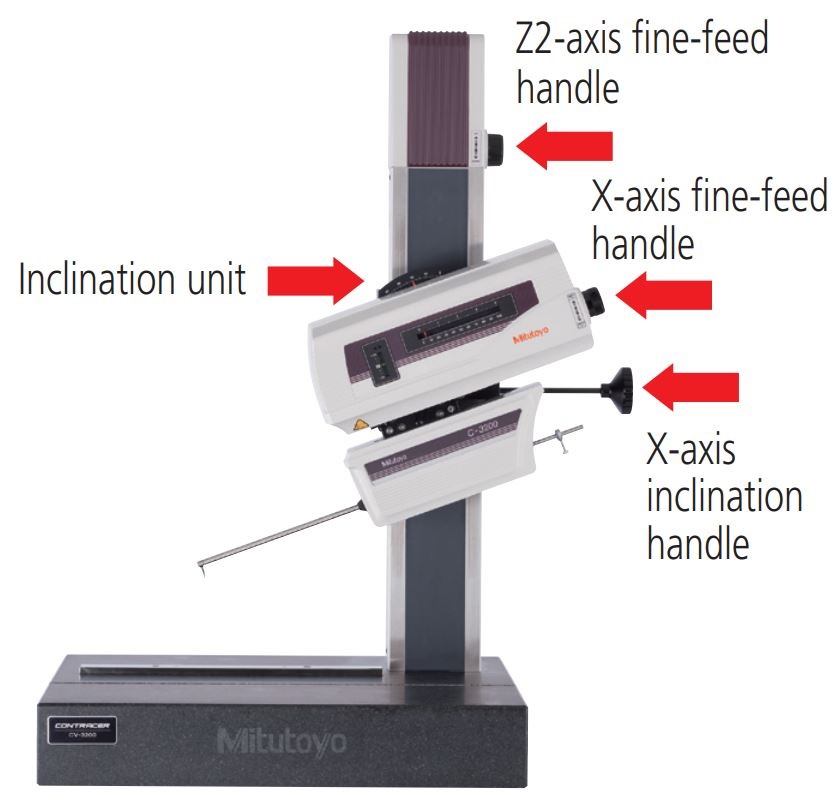

Small holes and inclined planes can be efficiently measured using the inclined X-axis drive unit and fine-feed handles on the X and Z2 axes.

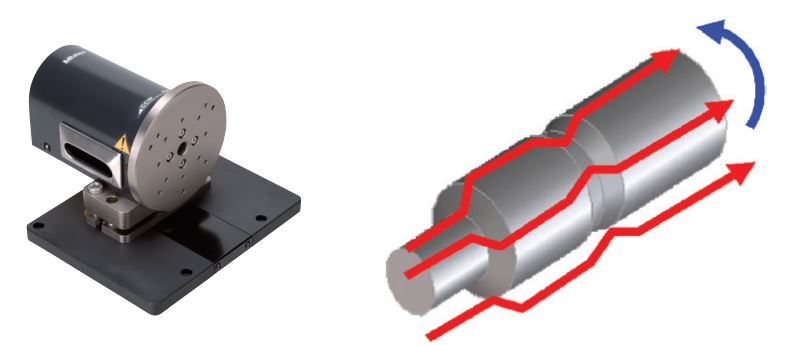

With the support for a wide range of optional peripherals designed for use with the CNC Form Measuring Unit enables simplified CNC measurement.

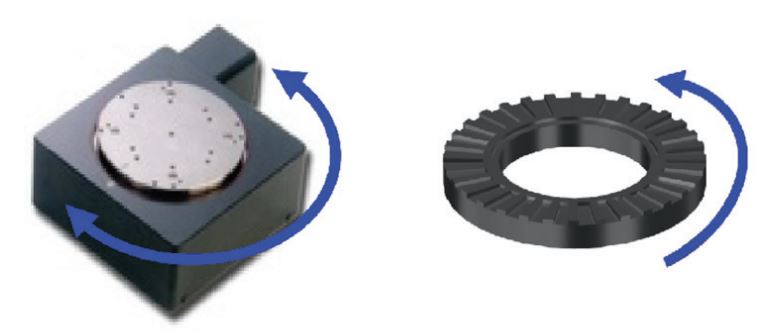

• Ø1-axis Rotary unit: Automatic circular-form measurement

• 2-axis Rotary unit: Automatic multiple-section continuous measurement

| Model | CV-3200H4 | ||

| Measuring range | X axis | 100mm | |

| Z2 axis (column) travel range 3 | 60mm (±30mm in horizontal situation) | ||

| Z2 axis (column) travel range 3 | 500mm | ||

| Detector (Z1 axis (detector unit)) | Scale unit | Arc scale | |

| Resolution | 0.04µm | ||

| Stylus up/down motion | Arc movement | ||

| Measuring direction | Both pulling and pushing directions | ||

| Measuring face direction | Downward or upward | ||

| Measuring force | 30mN (by adjusting weight) | ||

| Stylus traceable range | Ascent 77°, Descent 83° (with one-sided cut stylus: standard accessory) | ||

| Drive unit | Scale unit | X axis | Separate type linear encoder |

| Z2 axis (column) | ABS encoder | ||

| Resolution | X axis | 0.05µm | |

| Z2 axis (column) | 1µm | ||

| Drive speed | X axis | 0 – 80mm/s and manual operation | |

| Z2 axis (column) | 0 – 30mm/s and manual operation | ||

| Measuring speed | X axis | 0.02 – 20mm/s | |

| Straightness (when the X axis is horizontal) | X axis | 0.8µm/100mm | |

| X axis inclination angle | X axis | ±45° | |

| Accuracy (20°C) | CV-3200 | X axis | ±(0.8 + 0.01L) µm L = Drive length (mm) Wide range: 1.8µm/100mm Narrow range: 1.05µm/25mm |

| Z1 axis (column) | ± (1.4 + | 2H | /100) µm H = Measurement height from the horizontal position | ||

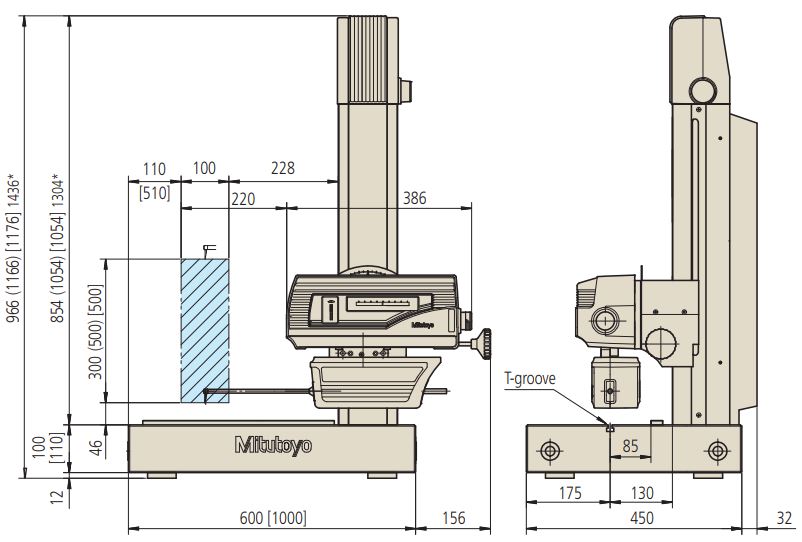

| External dimensions (W×D×H) | Main unit | 756×482 ×1166mm | |

| Controller | 221×344×490mm | ||

| Remote box | 248×102×62.2mm | ||

| Mass | Main unit | 150kg | |

| Controller | 14kg | ||

| Remote box | 0.9kg | ||

| Operating temperature range | 15 – 25°C (within ±1K temperature fluctuation on calibration and measurement) | ||

| Operating humidity range | 20 – 80%RH (with no condensation) | ||

| Storage temperature range | −10 to 50°C | ||

| Storage humidity range | 5 – 90%RH (with no condensation) | ||