Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on back-order

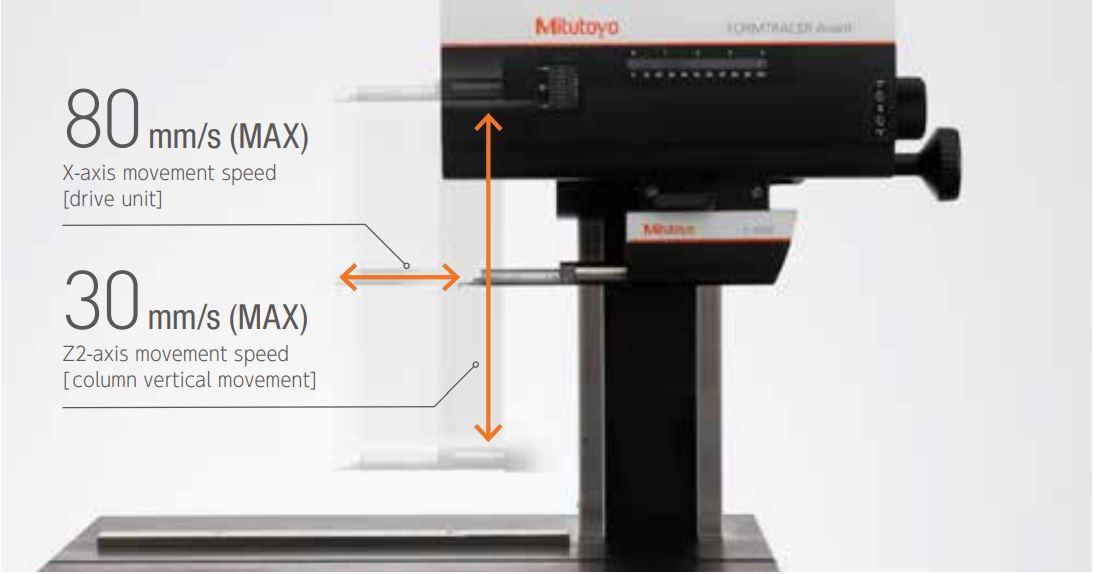

FORMTRACER Avant Series boasts best-in-class drive speed for both drive unit and column axis along with a quick stroke return speed. To establish “Speed up,” for surface roughness measurement, the positioning distance from the start of measurement to the start of data acquisition is reduced to the lowest limit. For contour measurement, the time from contact on a workpiece to the start of measurement is shortened. The total measurement time is drastically reduced to improve measurement efficiency.

X-axis (drive unit): 80 mm/s (MAX) Z2-axis (column vertical movement): 30 mm/s (MAX)

Speed-up of the movement enables reduction of the total measurement time.

The stroke (retraction) speed is improved by approx. three times compared to conventional models; meanwhile, the speed when the stylus goes down to touch a workpiece becomes slower in consideration of safety. The measuring system automatically detects the workpiece contact, then immediately moves into standby mode for the start of measurement approximately three times faster than a conventional model, for a drastic improvement in measuring efficiency.

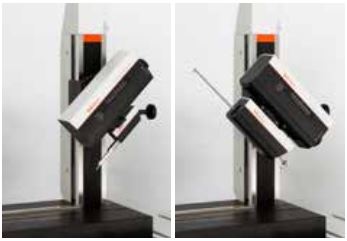

To measure inclined surfaces efficiently, an X-axis inclinable drive unit which can measure surfaces within a range of ±45° is mounted. When mounting the contour detector C-4500, the measuring force can be varied in 5 steps by using the software provided (FORMTRACEPAK), eliminating the need to adjust the measuring force by switching weights or through positional adjustment. This system can also maintain the specified measuring force even when inclined.

The system features a built-in precision arc scale that allows the circular trajectory of the stylus tip to be read directly, eliminating the need for an arc direct conversion mechanism, which often causes measurement error on the detector. It allows precision measurement over a wide range even if the arm is not in the horizontal attitude. You can perform precision measurement without worrying about the measurement range.

All detector and drive unit cables are housed inside the main unit to eliminate any risk of abrasion or snagging and guarantee precision measurement and rapid movement.

No need to turn the controller power off when replacing the contour detector or roughness detector; moreover, the tool-less replacement mechanism (thumb-turn clamper) greatly helps to reduce the replacement time by approx. 1/4 (approx. 30 seconds) compared to a conventional model. Further, positioning using the guide pin improves reproductivity when replacing detectors and allows efficient operation of the automatic measuring program.

|

Z1-axis range

[mm]: |

60

|

|

Granite base size

(WxD) [mm]: |

600 x 450

|

|

Model:

|

FTA – S4 C3000

|

|

Vertical travel

[mm]: |

300

|

|

Traverse:

|

100 mm

|

|

Measuring speed:

|

0.02 – 30 mm/s

|

|

Drive speed:

|

X: 0 – 80 mm/s; Z2: 0 – 40mm/s

|

|

Inclining range:

|

±45°

|

|

Software: |

FORMTRACEPAK

|

|

Traverse straightness:

|

0,8 µm / 100 mm

|

|

Measuring force:

|

30 mN

|

|

Inch-Metric:

|

Metric

|

|

Mass:

|

140 kg

|