Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics (A & B) and Light Force Brinell hardness testing.

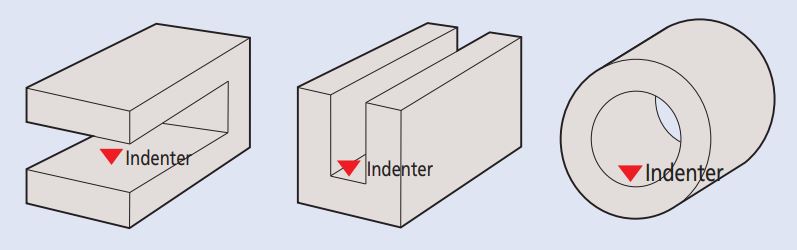

Test the hardness of the inside wall of a ring without cutting the ring into pieces. (All models.) Minimum diameter is 34 mm, but inside diameters as small as 22 mm can be tested by using the optional 5 mm diamond indenter (19BAA292).

The HM and HV series user interface has been adapted to include Rockwell hardness testing capabilities. Versatile color screens display the results of statistical calculations and graphics functions, etc.

A nose-type indenter enables measurement not only of the flat top surface of a specimen, but also the inside surface of a cylindrical specimen.

| Order No. | 810-231 | 810-232 | 810-236 | 810-237 | |

| Model | HR-530 | ||||

| Applicable standards | JIS B 7726, ISO 6508-2, ASTM E18*1 | ||||

| Hardness testing methods | Rockwell/Rockwell Superficial/Brinell/Plastics hardness | ||||

| Initial test force (N) | 29.42 98.07 | ||||

| Test force (N) | Rockwell Superficial | 147.1 294.2 441.3 | |||

| Rockwell | 588.4 980.7 1471 | ||||

| Brinell | 61.29 98.07 153.2 245.2 294.2 306.5 612.9 980.7 1226 1839 | ||||

| Test force control | Automatic (load/hold/unload) | ||||

| Table up/down mechanism | Manual (automatic braking and load sequencing) | ||||

| Control unit | Color touch-screen | ||||

| Test force switching | Operated with the display unit | ||||

| Test force hold time | 1 to 120s (Selectable in units of 1s) | ||||

| Maximum specimen size | Height: 250 mm Depth: 150 mm |

||||

| Permissible inside diameter of a pipe specimen | Minimum hole diameter: 35 mm (when using the special indenter: 22 mm) | ||||

| Maximum table loading | 20Kg | ||||

| Indenter type | Steel ball | Tungsten carbide ball | |||

| Unit (display unit) | metric | inch/mm | metric | inch/mm | |

| Display | Hardness value, test condition, GO/NG judgment result, statistical calculation result, X ̄-R control chart, hardness conversion value | ||||

| Conversion function [HV, HK, HR (Rockwell hardness A, B, C, D, F, G / Rockwell Superficial 15T, 30T, 45T, 15N, 30N, 45N), HS, HB, tensile strength] | |||||

| GO/NG judgment function | |||||

| Continuous test function (for specimens with the same thickness) | |||||

| Cylindrical correction, spherical correction, offset correction, multi-point correction functions | |||||

| Statistical calculation function (Maximum value, minimum value, mean value, standard deviation, upper limit value, lower limit value, GO count, range, NG count) | |||||

| Graph generation function (X ̄-R control chart) | |||||

| External data output | RS-232C, digimatic, USB2.0 | ||||

| Power supply | AC100V, 120V, 220V, 240V Auto-selection | ||||

| External dimensions |

Main unit | 250(W)×667(D)×621(H) mm | |||

| Touch-screen display unit | 191(W)×147(D)×71(H) mm | ||||

| Mass | Approx. 60 kg | ||||