Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

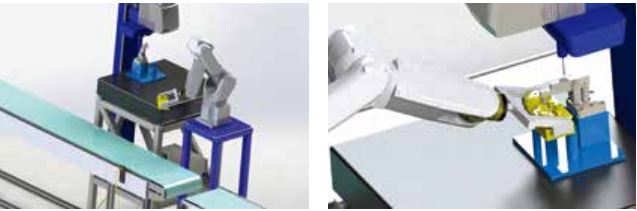

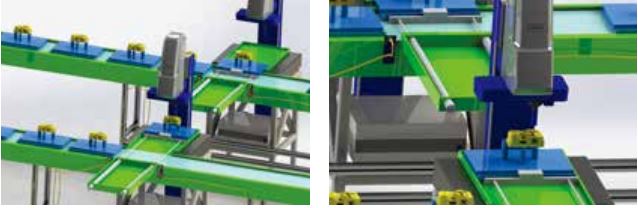

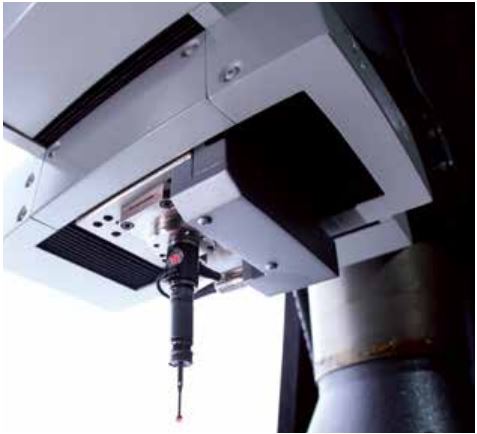

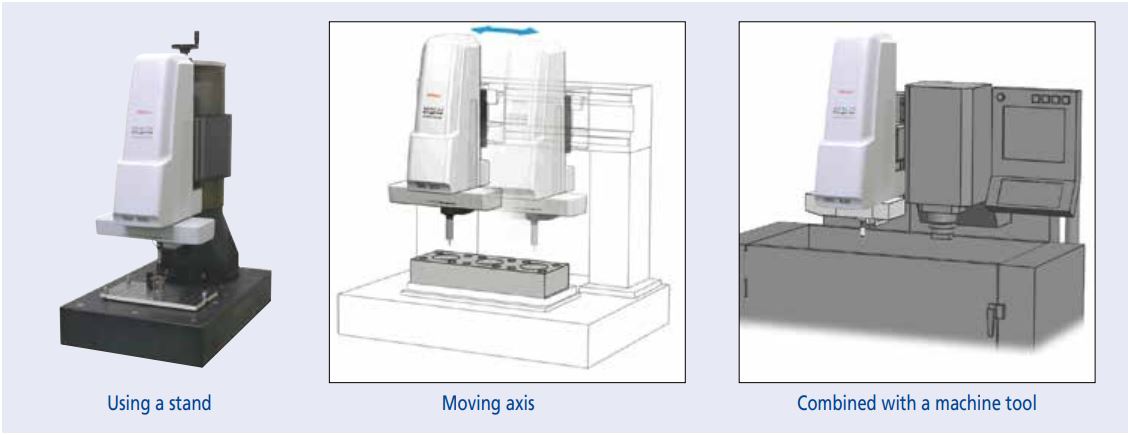

The MACH Ko-ga-me — a fast, compact, lightweight and easy-to-mount CMM — is the ideal solution for automated cells. The guaranteed accuracy temperature of 10°C to 35°C provides flexibility and performance in your production environment. Mounted on any rigid frame, including machine tools, the MACH Ko-ga-me will provide CMM capabilities without the space requirements of a full-sized machine and in-process measurement without setup and breakdown. The small-sized 3-axis CNC measuring head incorporates high accuracy and high speed with the flexibility to implement numerous configurations for inspection applications in the quality lab or directly within the manufacturing process. The MACH Ko-ga-me’s flexible design allows implementation to meet specific or multiple manufacturing applications:

Versatility

Versatility of the MACH Ko-ga-me allows for quick and easy setup of applications. Modifications can be made on the fly and when critical features in the manufacturing process change. Without expensive masters to maintain, once the A2LA certified calibration is complete, only a simple master ball style probe calibration is necessary to achieve the continuous rated accuracy.

Flexibility

Because the MACH Ko-ga-me is a compact CMM, it offers flexibility when production or manufacturing requirements change. It can be easily moved, reconfigured to handle a completely different part family or even used for general lab inspection. The MACH Ko-ga-me supports touch probe (TP200) or scanning probe (SP25) technology.

Speed

With a maximum drive speed of 13.3″/sec (340mm/s), and an acceleration of 6,750mm/s2 (0.68g), these high-speed capabilities provide the

MACH Ko-ga-me the ability to rapidly acquire critical features, allowing for a quicker feedback and compensation of the manufacturing process, reducing scrap and increasing throughput.

Minimal Site Preparation

With only a 120V 15A power requirement, no requirement for compressed air and a small footprint, the MACH Ko-ga-me can be used almost anywhere a need exists. The lightweight design allows for the unit to mount easily anywhere within the manufacturing process.

Automation Ready

Using standard features of MCOSMOS, the world’s standard in metrology software, MACH Ko-ga-me easily interfaces into factory automation and manufacturing cells. With extended I/O capability, interface to robots, conveyors, clamps and sensors is seamless.

Guide Method

By utilizing a linear motion bearing design instead of air bearings, the MACH Ko-ga-me performs high-speed measuring without sacrificing accuracy.

Environment

Designed to be used on the shop floor, using a sealed design and built-in thermal compensation, the MACH Ko-ga-me is accurate within a temperature range of 50~95º F (10~35º C).

| Automotive/ATV/Marine | |

| Pump Housings | Rocker Arms |

| Motors | Alternator Housings |

| Pistons | Bearing Races |

| Filter Assemblies | Piston Rods |

| Brake Components | Wheel Hubs |

| Fuel Lines | Throttle Body |

| Aerospace | |

| Implants | Impellers |

| Pumps | Surgical Instruments |

| Energy (Oil/Gas/Solar/Wind/Nuclear) | |

| Flanges | Fittings |

| Pumps | Housings |

| Couplings/Connections | Hardware |

|

Model |

KGM12128-B |

|

Type |

3D CNC Flexible Gage |

|

Range |

X-4.72″ (120mm) |

|

Y-4.72(120mm) |

|

|

Z-3.14(80mm) |

|

|

Resolution |

0.00000078″(0.02µm) |

|

Guide Method |

Straight-motion hard bearing |

|

Maximum Drive Speed 3D |

13.38”/s (340mm/s) |

|

aximum Acceleration 3D |

0.68G (6,750mm/s2) |

|

Mass: main unit |

61.7lbs (28kg) |

|

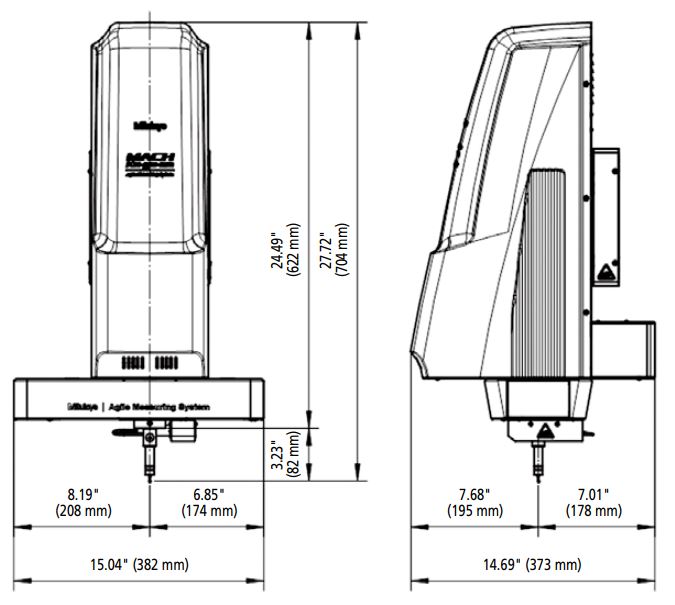

Macine Dimensions (WxDXH) |

15.03″x14.68″x30.90″ (382mmx373mmx785mm) |

|

Measuring Accuracy |

TP200/SP25: 19-21°C (66.2-69.8°F) (2.0+5.0L/1000)μm |

|

15-25°C (66.2-69.8°F) (2.3+5.7L/1000)μm |

|

|

10-30°C (50.0-86.0°F) (2.7+6.5L/1000)μm |

|

|

10-35°C (50.0-95.0°F) (3.0+7.2L/1000)μm |

|

|

Probing Error TP200/SP25: 2.0μm |

|

|

Scanning probing error SP25: 2.5μm |