Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

The world’s fastest CNC vertical axis, in-line coordinate measuring machine with world-beating acceleration (8,660mm/s2 ), measuring speed (at the moment of contact: 20mm/s) as well as drive speed. This system contributes to the reduction in total cost as an auto- measurement system, either in a line or at line side where a reduction in measurement time is required, and can also serve as a dedicated machine or a substitute system for gauges.

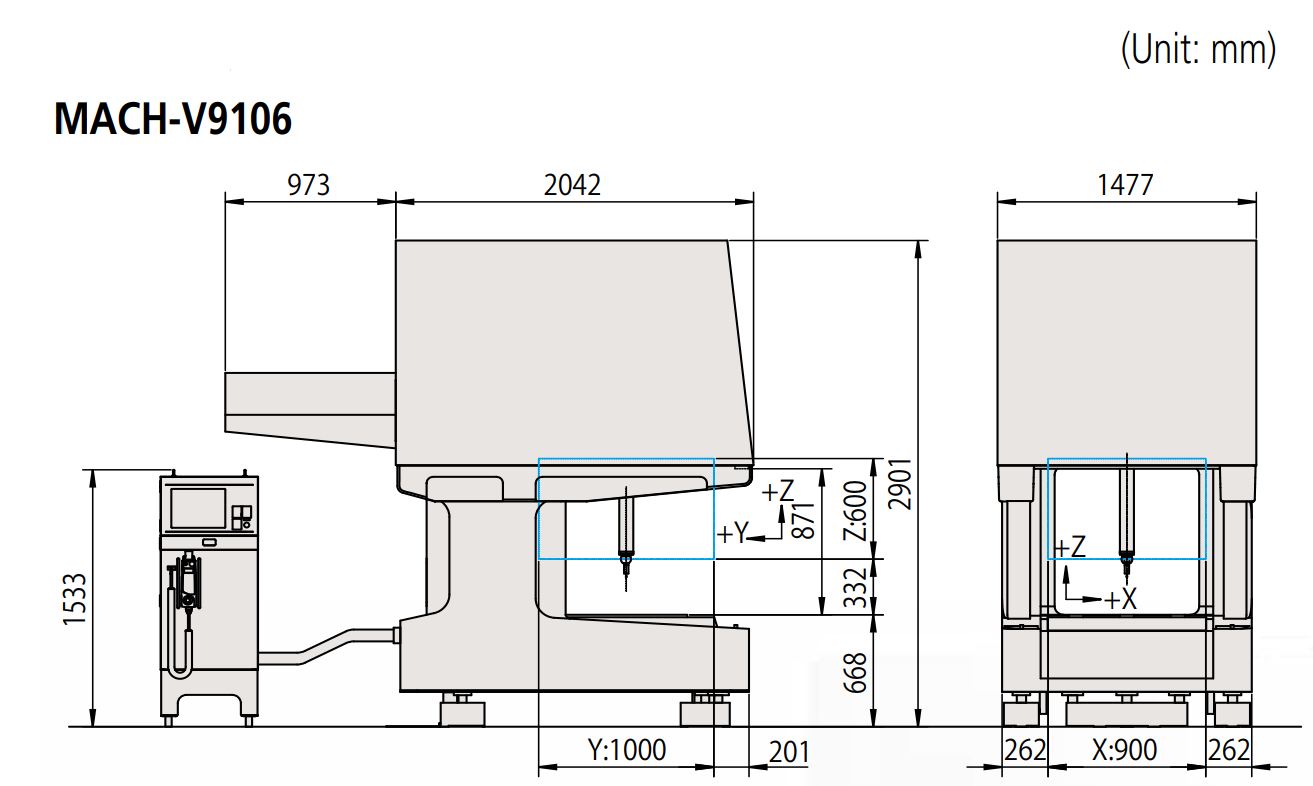

In consideration of installation between processing machines, the width of this machine has been reduced by 15% compared with its predecessor, thus contributing to a reduction in line length. Open access to the measuring area from the front/back and left/right has increased flexibility in the routing arrangements for a workpiece.

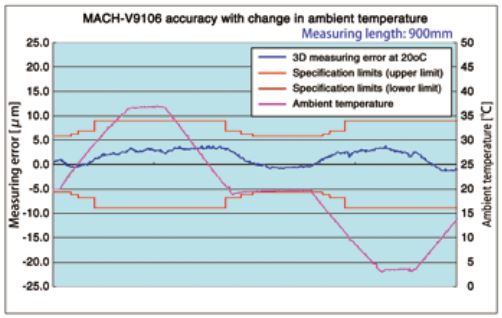

Real-time thermal compensation applied to measurements and origin- setting assure excellent accuracy (referred to 20°C) over a much wider range of ambient temperature than conventional CMMs. The graph below shows the effectiveness of the scheme in maintaining accuracy over a range of more than 30°C.

This series has improved dust resistance relative to its predecessor by installing all drive system and scale units in the dust-tight enclosure on the machine top. The control unit and PC are installed in the dust-tight rack.

The ease-of-maintenance construction and air-free operation means less chance of maintenance problems occurring.

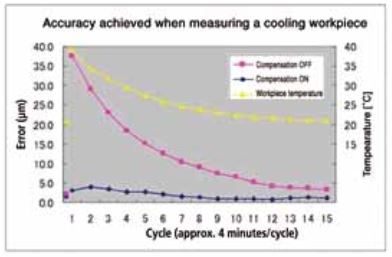

Generally, during production, the temperature of a workpiece differs from that of the measuring machine due to processing and washing and is always changing. To support in-line operations, the machine must continue accurate measurement (referred to 20°C) even while the size of a workpiece is changing due to this temperature difference. The following graph shows the high degree of compensation resulting when a MACH-V series machine (at 20°C) measured a certain workpiece while it cooled from 40°C towards 20°C.

| Model | MACH V9106 |

| Order No. | 360-226A |

| Type | Horizontal Arm High Speed, In-line |

| Range | X-35.43″ (900mm)

Y-39.36″ (1000mm) Z-23.62″ (600mm) |

| Resolution | 0.0000039″ (0.0001mm) |

| Guide Method | Mechanical bearing on each axis |

| Maximum Drive Speed 3D Maximum Acceleration 3D |

34.09”/s (866mm/s) 0.88g (8660mm/s2) |

| Work Table | Material-Steel

Size- Tappered Insert-M8x1.25mm |

| Workpiece | Height-31.49″(800mm)

Weight-150lbs330kg |

| Mass (including stand and controller) | 9,105lbs4130kg |

| Dimension | 58.14×115.85×114.17in 1447x2942x2900mm |

| ISO | ISO-10360-2:2009 E0,MPE

19-21°C (66.2-69.8°F) (2.5+3.5L/1000)μm TP7/SP25: 15-25°C (59.0-77.0°F) (2.9+4.3L/1000)μm ISO-10360-4 MPETHP/MPTTHP† ISO-10360-5: 2010 PFTU,MPE |