Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

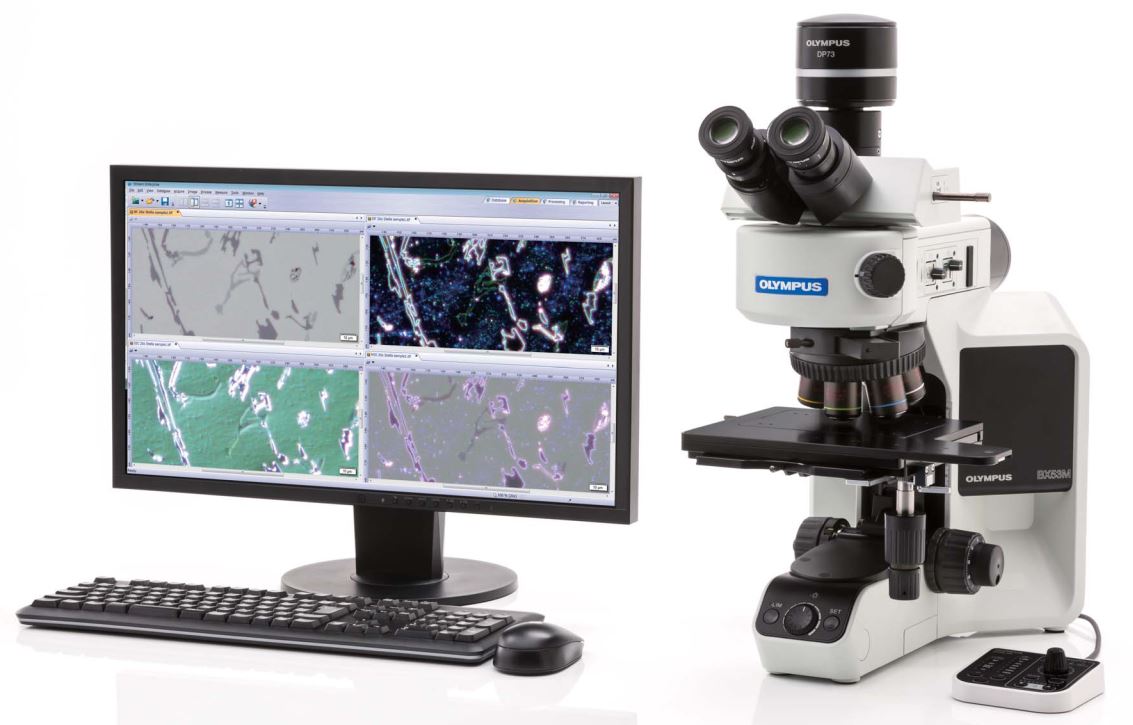

Designed with modularity in mind, the BX3M series provide versatility for a wide variety of materials science and industrial applications. With improved integration with OLYMPUS Stream software, the BX3M provides a seamless workfl ow for standard microscopy and digital imaging users from observation to report creation.

The illuminator minimizes complicated actions that are usually necessary during microscope operation. A dial at the front of the illuminator enables the user to easily change the observation method. An operator can quickly switch between the most frequently used observation methods in reflected light microscopy, such as from brightfield, to darkfield, to polarized light, in order to readily change between different types of analyses. In addition, simple polarized light observation is adjustable by rotating the analyzer.

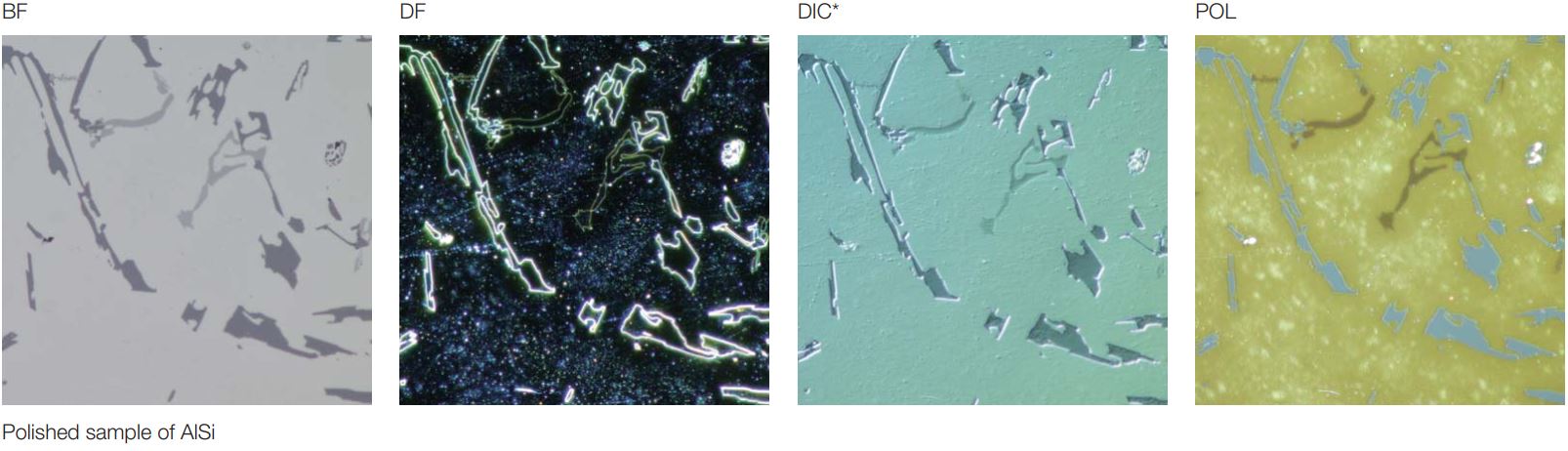

Reflected light microscopy spans a range of applications and industries. These are just a selection of examples of what can be achieved using different observation method

|

|

BX53MTRF-S |

BX53MRF-S |

BXFM |

|

|

Optical system |

UIS2 optical system (infinity-corrected) |

|||

|

Microscope frame |

Illumination |

Reflected/transmitted |

Reflected |

|

|

Focus |

Stroke: 25 mm |

Stroke: 30 mm |

||

|

Fine stroke per rotation: 100 μm |

Fine stroke per rotation: 200 μm |

|||

|

Minimum graduation: 1 μm |

Minimum graduation: 2 μm |

|||

|

With upper limit stopper, torque adjustment for coarse handle |

With torque adjustment for coarse handle |

|||

|

Max. specimen height |

35 mm (w/o spacer) |

65 mm (w/o spacer) |

Depends on the mounting configuration |

|

|

75 mm (with BX3M-ARMAD) |

105 mm (with BX3M-ARMAD) |

|||

|

Observation tube |

Wide-field FN 22 |

Inverted: binocular, trinocular, tilting binocular |

||

|

Erect: trinocular, tilting binocular |

||||

|

Super-wide-field FN 26.5 |

Inverted: trinocular |

|||

|

Erect: trinocular, tilting trinocular |

||||

|

Reflected light illumination |

Traditional observation technique |

BX3M-RLAS-S |

||

|

Coded, white LED, BF/DF/DIC/POL/MIX FS, AS (with centering mechanism) |

||||

|

BX3M-KMA-S |

||||

|

White LED, BF/DIC/POL/MIX FS, AS (with centering mechanism) |

||||

|

BX3M-RLA-S |

||||

|

100W halogen lamp, white LED, BF/DF/DIC/POL/MIX/ FS, AS (with centering mechanism), |

||||

|

BF/DF interlocking, ND filter |

||||

|

– |

U-KMAS |

|||

|

White LED, 100W halogen |

||||

|

Fiber illumination, BF/DIC/POL/MIX |

||||

|

Fluorescence |

BX3M-URAS-S |

|||

|

Coded, 100W mercury lamp, 4 position mirror unit turret, (standard: WB, WG, WU+BF etc) |

||||

|

With FS, AS (with centering mechanism), with shutter mechanism |

||||

|

Transmitted light |

White LED |

– |

||

|

Abbe/long working distance condensers |

||||

|

Revolving nosepiece |

For BF |

Sextuple, centering sextuple, septuple, coded quintuple (optional motorized revolving nosepieces) |

||

|

For BF/DF |

Sextuple, quintuple, centering quintuple, coded quintuple (optional motorized revolving nosepieces) |

|||

|

Stage |

Coaxial left (right) handle stage: |

– |

||

|

76 mm × 52 mm, with torque adjustment |

||||

|

Large-size coaxial left (right) handle stage: |

||||

|

105 mm × 100 mm, with locking mechanism in Y-axis |

||||

|

Large-size coaxial right handle stage: |

||||

|

150 mm × 100 mm, with torque adjustment and locking mechanism in Y-axis |

||||

|

Weight |

Approx. 18.3 kg |

Approx. 15.8 kg |

Approx. 11.1 kg |

|

|

(Microscope frame 7.6 kg) |

(Microscope frame 7.4 kg) |

(Microscope frame 1.9 kg) |

||