A CNC system that combines high accuracy with automatic CNC measurements to greatly improve productivity and efficiency. Automatic orientation control for the detector unit enables this system to automatically execute high-speed, operator-less measurements. Available with the standard column specification (Z-axis traverse of 350mm) or an extended specification (Z-axis traverse of 550mm) for handling taller workpieces.

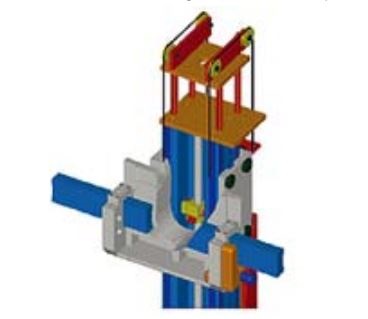

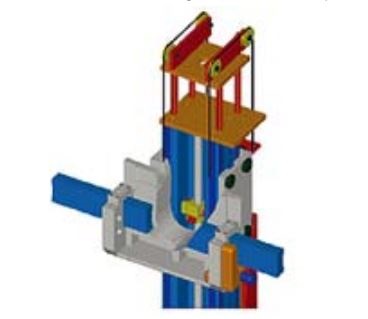

Detector unit orientation programmable for CNC measurement

| This function controls the orientation of the arm holding the detector unit (between vertical and horizontal) and the detector unit rotation mechanism (between 0 and 270 degrees in 1-degree increments), making it possible to continuously and automatically measure internal/external diameters as well as top/ bottom surfaces. Additionally, a full-featured offline teaching function simplifies the creation of part programs. |

|

Surface-roughness measuring function (optional roughness unit)

| The system is a multi-sensor type, compatible both with a standard probe that meets the specifications of the roundness measuring system and a surface roughness detector unit. Incorporating the optional roughness detector unit into the system enables roughness measurement in the circumferential direction around the θ-axis, as well as in the direct-drive directions along the X- and Z-axes with the table stopped. Thus, surface roughness and geometric tolerances, such as roundness and cylindricity, can both be validated using only a single system. |

|

World-Class Accuracy

High-accuracy, automatic centering/leveling turntable

| A highly accurate, highly rigid turntable has been achieved through exceptional manufacturing accuracy of the critical components, in addition to a high-accuracy air-bearing that provides superior rigidity. The resulting rotational accuracy, the heart of the roundness/cylindricity measuring system, is world-class at (0.02+3.5H/10000)μm. |

|

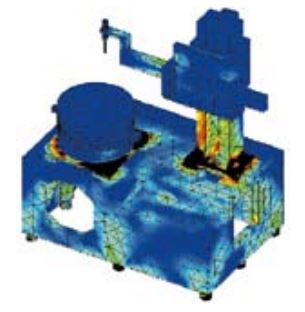

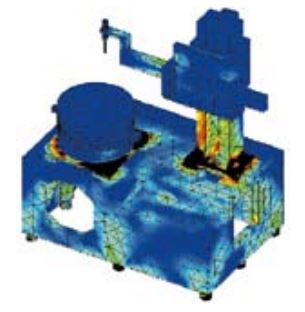

High-rigidity base

For a measurement system to be able to achieve high accuracy, the base, which forms the foundation of the system, must be completely rigid. Therefore, we utilized FEM structural analysis simulation to thoroughly analyze the base and its application. The result is the development of a high-rigidity base.

High-accuracy Z-axis column

Attaining the ultimate level of improvement in the manufacturing accuracy of the column guide surface, which is critical for achieving perfect straightness, and adopting Mitutoyo’s proprietary system and mechanisms have led to the achievement of the ultra-high column straightness of 0.05μm/100mm (in narrow range)

High-accuracy positioning sensors

High-speed automatic centering/leveling

The system is supplied as standard with the Automatic Adjustment Table (A.A.T.) positioning and leveling function, freeing the operator from the task of centering and leveling the workpiece. High- precision glass encoders are used to reduce positioning errors and achieve high-speed automatic centering/leveling, which contributes greatly to reducing the total measurement time from workpiece setting to workpiece measurement.

Measurement through X-axis tracking

| Measurement while tracing is possible through a built-in linear scale in the X-axis. This type of measurement is useful when displacement due to form variation exceeds the measuring range of the sensor, and X-axis motion is necessary to maintain contact with the workpiece surface. |

|

Safety mechanism provided as a standard feature

| A safety mechanism is incorporated into the detector unit area. A collision- sensing function has been added to the detector unit (when it is in the vertical orientation) to prevent collision in the Z-xis direction. Additionally, an accidental collision prevention function, which stops the system when the detector unit displacement exceeds its range, has been added. When an accidental touch is detected, the dedicated analysis software (ROUNDPAK) senses the error and automatically stops the system. |

|