Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

This is a compact roundness tester with D.A.T. (Digital Adjustment Table) function.

Available on backorder

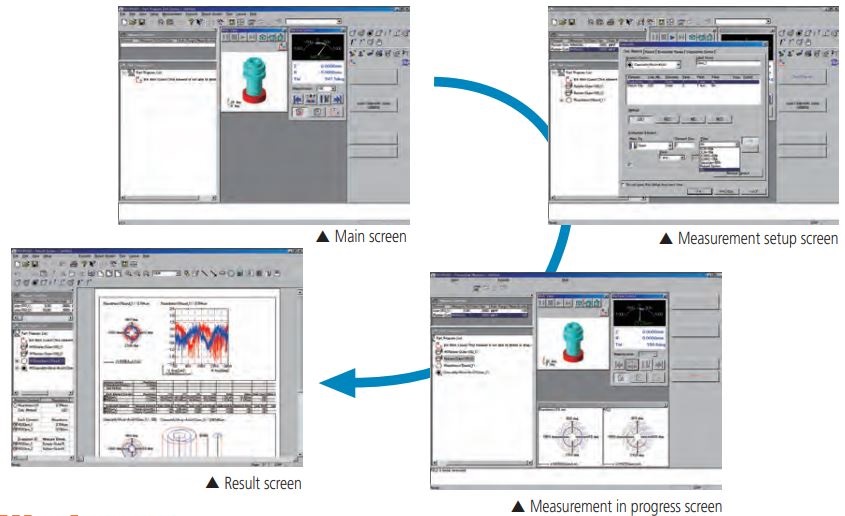

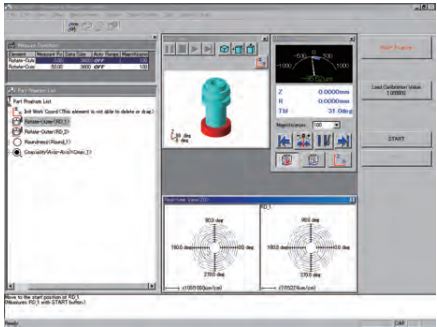

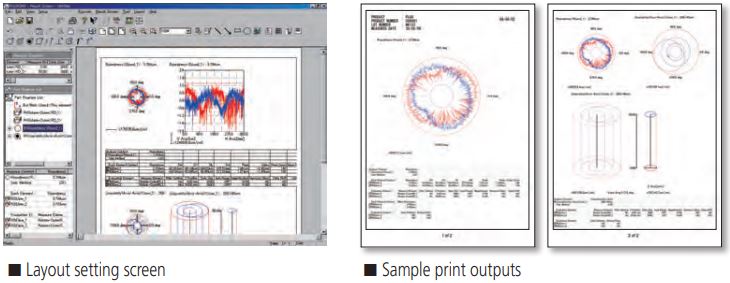

By using a mouse and buttons, identified by corresponding icons, to control the machine, the Roundtest RA-120P’s interface provides excellent usability. Functions such as recalculation and graph reading are handled swiftly with easy-to-understand operations.

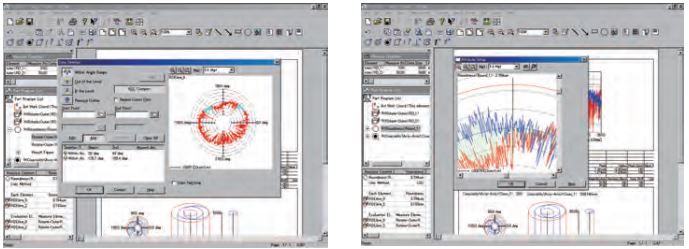

Complete with a wide range of functions including partial enlargement, auxiliary line setup, color change, displacement/angular difference of data between two points. Also equipped with notch processing and graph reading functions, which make the machine useful in research departments. Recalculation can also be performed when the filter and evaluation method is changed.

| Model | RA-120P |

| Turntable | |

| Rotational accuracy: | (0.04+6H/10000)µmH: Probing height (mm) |

| Rotating speed: | 6rpm |

| Table top diameter: | ø 1.96” (150mm) |

| Centering range | :±.12” (3mm) |

| Leveling range: | ±1° |

| Maximum probing diameter: | ø 11” (280mm) |

| Maximum workpiece diameter: | ø 17.3” (440mm) |

| Maximum workpiece weight: | 55 lbs (25kg) |

| Vertical column (Z-axis) | |

| Vertical travel: | 11” (280mm) |

| Feeding: | 1.18” (30mm)/rev. (coarse) 0.039” (1mm)/rev. (fine) |

| Maximum probing height: | 11” (280mm) from the turntable top |

| Maximum probing depth: | 3.94” (100mm) (min. ID: 1.18”(30mm) |

| Horizontal arm (X-axis) | |

| Horizontal travel: | 65” (165mm) (Including a protrusion of 1” (25mm) the turntable rotation center) |

| Probe and stylus | |

| Measuring range: | ±1000μm |

| Measuring force: | 7 to 10mN |

| Standard stylus: | 12AAL021, carbide ball, ø1.6mm |

| Measuring direction: | Two directional |

| Stylus angle adjustment: | ±45° (with graduations) |

| Data analysis unit: | |

| Data sampling points: | 3,600 points/rotation |

| Data analysis items: | Roundness, Coaxiality, Concentricity, Flatness, Circular runout (radial), Circular runout (axial), Squareness (against axis), Squareness (against plane), Thickness deviation, Parallelism |

| Reference circles for roundness evaluation: | LSC, MZC, MIC, MCC Recording device: |

| Recording device: | Built-in thermal line printer |

| Recording magnification: | X1 to X500,000 |

| Roughness component reduction: | Low pass filter, band pass filter |

| Filter type: | 2CR-75%, 2CR-50%, 2CR-75% (phase corrected) 2CR-50% (phase corrected), Gaussian, filter OFF |

| Cutoff value: | 15upr, 50upr, 150upr, 500upr, Manual 15-150upr, 15-500upr, 50-500upr, Manual |

The turntable displays centering and leveling adjustments digitally, making this challenging task easy enough for even an untrained operator to perform, through these four simple steps:

1. Preliminary measurement of two cross sections on the workpiece.

2. The centering and leveling adjustment values are displayed.

3. The digital micrometer heads on the rotary table are adjusted to match the values displayed.

4. Centering and leveling is complete. [Centering range : ±3 mm – Leveling range : ±1°]