Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Open time: 8 : 00 AM - 5 : 30 PM (Monday - Saturday)

Available on backorder

7.5 Color TFT LCD

The dedicated data processor has a high-visibility 7.5″ color TFT LCD. Icon display and touch panel operation provide user-friendly display and easy operation.

Positioning by joystick and manual control knobs on the processor

Easy-to-operate joystick. Fine positioning of stylus required for small-hole measurements can be easily performed using the manual fine-adjustment knobs.

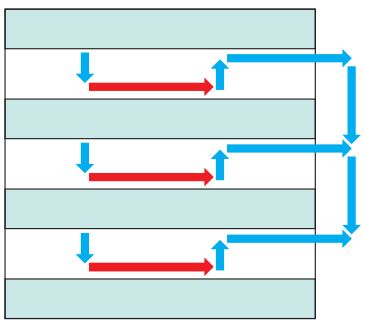

Multiple trace function

A machine can be programmed to take up to three traces, one after the other.

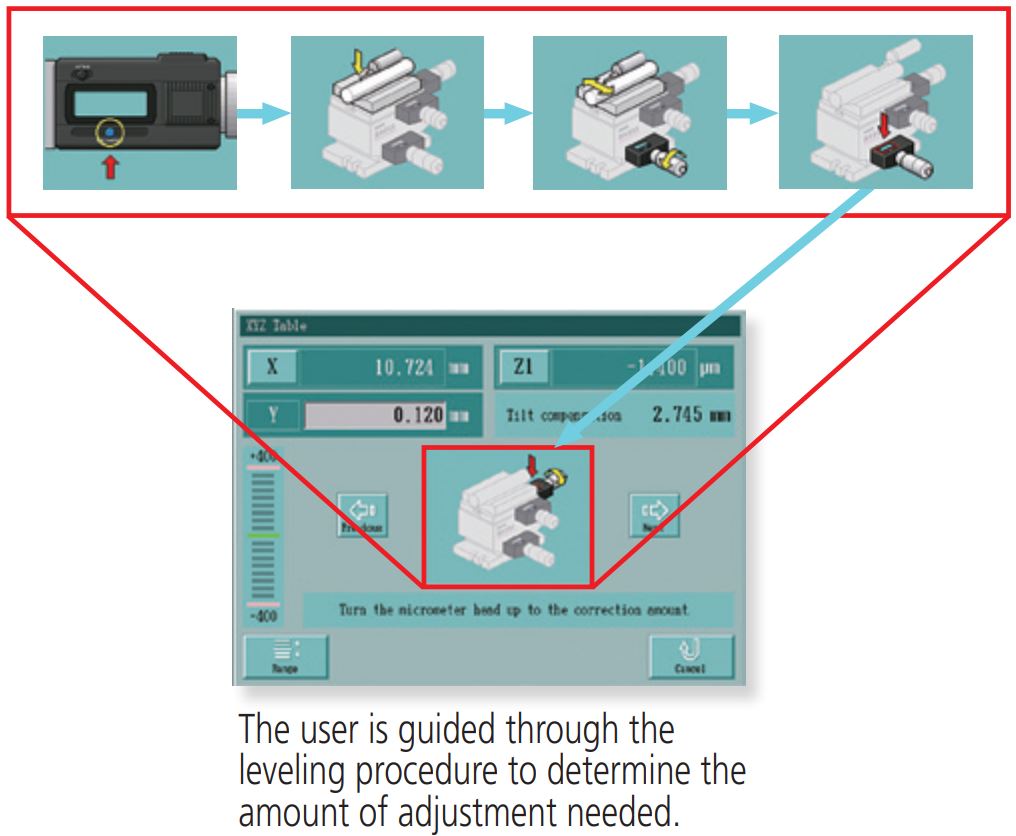

Auto leveling table (optional)

Automatically levels the surface to be tested for easy, strain-free setup.

Capable of fine-contour analysis

Supports 43 types of analysis parameters, complying with surface roughness standards such as ISO 1997 and JIS 2001. Also capable of various fine-contour analysis.

* Contour analyses: Area, circle, angle, coordinate difference, step, inclination

Ceramic guideway

A ceramic guideway, inherently free from wear and deterioration with age, is employed to maintain the traversing straightness of the drive unit (X-axis) indefinitely. Maintenance-free design, ince anti-corrosion treatment is not required for ceramic.

A high-visibility 7.5″ color TFT LCD, color icon display and touchoperated panel provide user-friendly, easy operation. Built-in thermal printer. Fine contour analysis provided as standard.

Supports 16 languages

Japanese, English, German, French, Italian, Spanish, Portuguese, Korean, Simplified Chinese, Traditional Chinese, Czech, Polish, Hungarian, Turkish, Swedish, Dutch

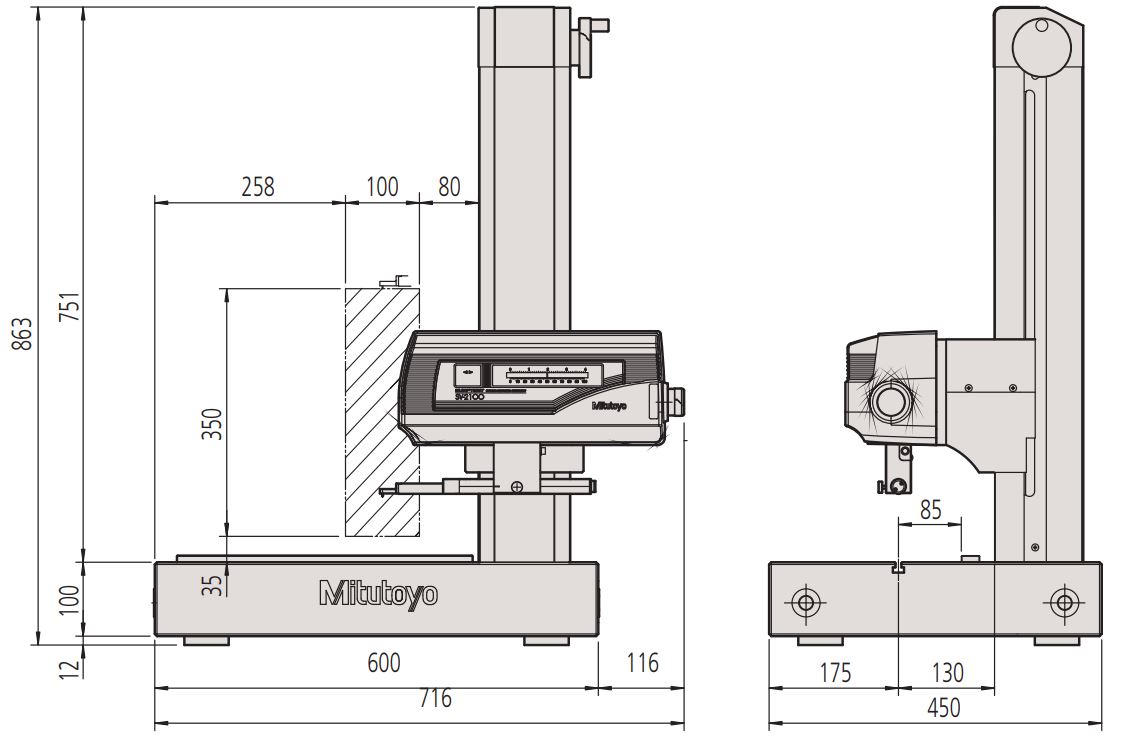

SV-2100S4/H4/W4

X-axis tracing with programmed Z-axis shifts possible

Both a fast-traverse joystick (X-axis: .78″/s (20mm/s) for SJ-500, 1.98″/s (40mm/s) for SV-2100, Z2-axis: .78″/s (20mm/s) for SV2100S4/H4/W4) and manual fine-adjustment knobs, essential or positioning in small hole measurement, are standard features.

When using an optional 3-axis adjustment table or leveling table, a navigation screen is available to help the operator level the surface to be tested.

|

Traverse:

|

100 mm

|

|

Measuring speed:

|

0.02 – 5 mm/s

|

|

Drive speed:

|

X = 0-40 mm/s

Z2 = 0-20 mm/s or joystick operation |

|

Traverse straightness:

|

0,15 µm / 100 mm

|

|

Measuring method:

|

Skidless – Differential inductance

|

|

Range:

|

800 µm; 80 µm; 8 µm

(up to 2,4 mm with an optional stylus) |

|

Profiles:

|

Primary Profile (P), Roughness Profile (R), Waviness (W), MOTIF (R, W) and more

|

|

Standard:

|

EN ISO, VDA, JIS, ANSI and customize settings

|

|

Analysis graphs:

|

BAC, ADC

|

|

Digital filter:

|

Gauss, 2CR75, PC75, RobustSpline

|

|

Cut-off length:

|

λc : 0.025 mm; 0.08 mm; 0.25 mm; 0.8 mm; 2.5 mm; 8 mm; 25 mm;

80 mm λs : 0.25 µm; 0.8 µm; 2.5 µm; 8 µm; 25 µm; 80 µm; 250 µm; none λf : 0.08 mm; 0.25 mm; 0.8 mm; 2.5 mm; 8 mm; 25 mm; 80 mm; none |

|

Printer:

|

Built-in thermal type

|

|

Display:

|

7.5″ colour TFT with backlight

|

|

Power supply report:

|

UN 38.3 Test Summary Report

|